cost to bend sheet metal These include reducing cost and allowing for improved strength, simplified assembly and little-to-no tooling. This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages . Enswell, sometimes called end-swell, endswell, stop-swell, no-swell or eye iron, is a small piece of metal with a handle. It is traditionally kept on ice and is used to cool the area of a bruise or a cut by applying direct pressure to decrease the blood flow to the area.

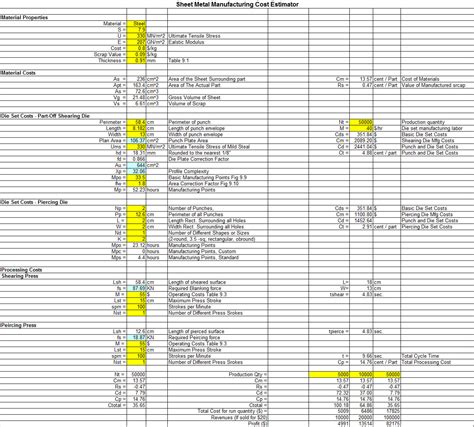

0 · sheet metal production cost calculator

1 · sheet metal parts cost estimator

2 · sheet metal manufacturing costs

3 · sheet metal fabrication cost estimator

4 · sheet metal fabrication cost

5 · sheet metal cutting cost

6 · sheet metal cost calculator

7 · dallan sheet metal manufacturing cost

Once a wire type is determined for your welding equipment, two additional pieces of information are needed in order to purchase this consumable. The first is the wire diameter, which is usually given in thousands of an inch. The most .

sheet metal production cost calculator

Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet . Sheet metal fabrication cost . Several other design considerations can help keep costs low: Utilize Optimal Bend Radius: Bend radius should always be optimized because .Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): Bend radius (in): Bend angle (°): K-factor: Setback (in): Bend .These include reducing cost and allowing for improved strength, simplified assembly and little-to-no tooling. This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages .

Manufacturing price of processes such as blanking, welding, painting. Instant online quote. Results from the calculation can help you analyze and negotiate prices with suppliers. One-stop shopping for projects that require multiple . Throughout this article, we will explore the cost elements, offering a step-by-step guide on calculating sheet metal fabrication expenses. We will also analyze how the quantity of parts can influence the unit cost, providing .Our CNC sheet metal bending services are here to turn your 2D project into a 3D part. Starting at per order. Get a quote today.

The cost of bending sheet metal is less than manually installing hardware like fasteners. You can decrease the number of fasteners you use by attaching two parts with a . Get a detailed breakdown of sheet metal fabrication costs, including material, labor, and equipment expenses. Learn how to save money on your next project with expert tips from MachineMFG.Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet metal fabrication quote.How to calculate the cost of sheet metal products considering cost of raw material, machining processes and the entire production cycle.

Sheet metal fabrication cost . Several other design considerations can help keep costs low: Utilize Optimal Bend Radius: Bend radius should always be optimized because proper bend radius optimization can save time as well as material. The internal bend radius should typically be greater than 0.030 inches and less than 1x the material .Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): Bend radius (in): Bend angle (°): K-factor: Setback (in): Bend allowance (in): Bend deduction (in): . Cost Estimators. Injection Molding Estimator; Machining Estimator; Die Casting Estimator;These include reducing cost and allowing for improved strength, simplified assembly and little-to-no tooling. This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

Manufacturing price of processes such as blanking, welding, painting. Instant online quote. Results from the calculation can help you analyze and negotiate prices with suppliers. One-stop shopping for projects that require multiple manufacturing processes, from metal fabrication to plastic molding. Throughout this article, we will explore the cost elements, offering a step-by-step guide on calculating sheet metal fabrication expenses. We will also analyze how the quantity of parts can influence the unit cost, providing practical .

Our CNC sheet metal bending services are here to turn your 2D project into a 3D part. Starting at per order. Get a quote today.

The cost of bending sheet metal is less than manually installing hardware like fasteners. You can decrease the number of fasteners you use by attaching two parts with a bend or combining two panels into one.

Get a detailed breakdown of sheet metal fabrication costs, including material, labor, and equipment expenses. Learn how to save money on your next project with expert tips from MachineMFG.

Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet metal fabrication quote.How to calculate the cost of sheet metal products considering cost of raw material, machining processes and the entire production cycle. Sheet metal fabrication cost . Several other design considerations can help keep costs low: Utilize Optimal Bend Radius: Bend radius should always be optimized because proper bend radius optimization can save time as well as material. The internal bend radius should typically be greater than 0.030 inches and less than 1x the material .Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): Bend radius (in): Bend angle (°): K-factor: Setback (in): Bend allowance (in): Bend deduction (in): . Cost Estimators. Injection Molding Estimator; Machining Estimator; Die Casting Estimator;

These include reducing cost and allowing for improved strength, simplified assembly and little-to-no tooling. This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

sheet metal parts cost estimator

Manufacturing price of processes such as blanking, welding, painting. Instant online quote. Results from the calculation can help you analyze and negotiate prices with suppliers. One-stop shopping for projects that require multiple manufacturing processes, from metal fabrication to plastic molding. Throughout this article, we will explore the cost elements, offering a step-by-step guide on calculating sheet metal fabrication expenses. We will also analyze how the quantity of parts can influence the unit cost, providing practical .

Our CNC sheet metal bending services are here to turn your 2D project into a 3D part. Starting at per order. Get a quote today.

metal framing angle brackets

It is a SIM removal tool. It is convenient to have should you ever need to change the SIM. Paper clips also work.

cost to bend sheet metal|sheet metal production cost calculator